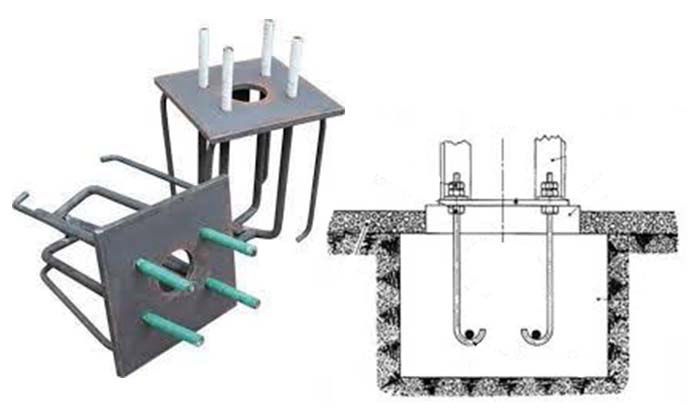

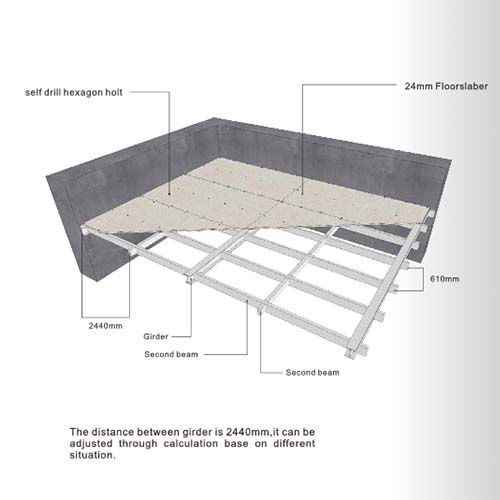

Général

Conception

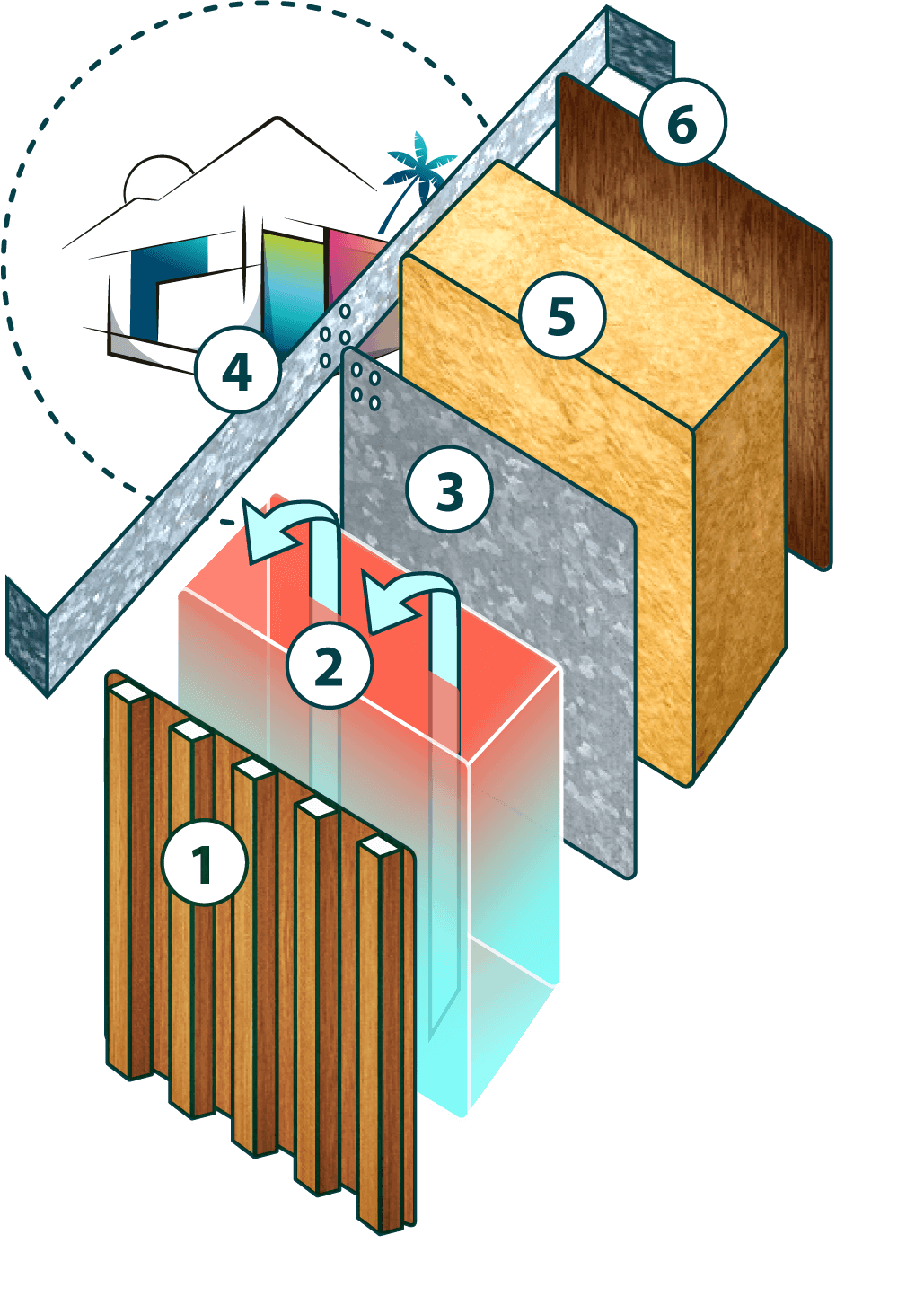

All structures are designed and manufactured by teams of engineers using CAD. Buildings are sized to meet climatic, architectural, technical, and budgetary operational constraints and are designed to be assembled as simply and quickly as possible. Without compromising on the aesthetics, comfort, and durability of the structures, the guiding principle that informs all studies is: time-saving.